The Leading Printed Circuit Board Manufacturer and PCB Assembly -Shinelink Technology Ltd

We Offer a Full Range of Printed Circuit Board, PCB Capabilities to

Fit All of Your PCB Needs.

Shinelink Technology Ltd founded in the year 2005, located in Shenzhen,China. is an expert

at PCB manufacturer and PCBA manufactur, based in Shenzhen,

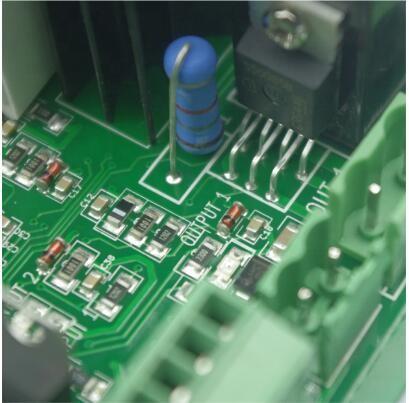

Guangdong, China. We are specialized in manufacturing Single-Sided

Boards, Double-Sided Boards and multilayer PCB, up to 20 layers.

also could provide components purchase and turnkey pcb assembly

service.

With more than A decade in the field of PCB prototype and

fabrication, we are committed to meeting the needs of our customers

from different industries in terms of quality, delivery,

cost-effectiveness and any other demanding requests. As one of the

most experienced PCB manufacturers in China, we pride ourselves to

be your best business partners of your PCB needs.

We are honored as the excellent supplier of many companies all

around this world. We can offer all kinds of services including PCB

manufacturing and PCB assembly sample orders and batch orders. For

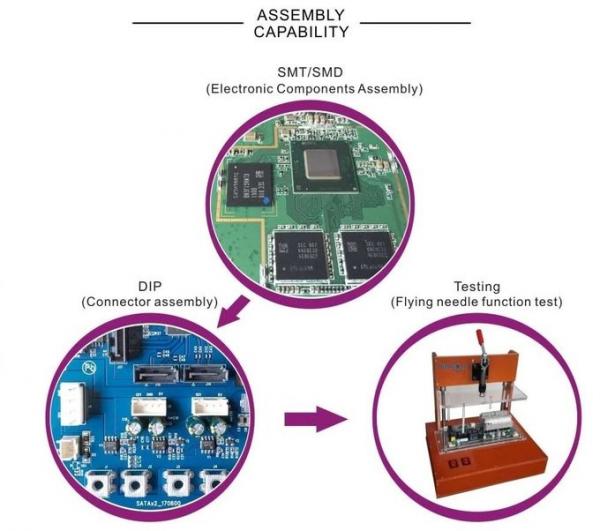

pcb assembly, utilizing 8 high-speed SMT pcba lines from Yamaha and

Sony, to meet our customers' need.

One Stop Solution -- Beyond PCB Manufacturing

We have got the ISO9001:2000, ISO14001, UL and ROHS certifications.

Now our PCB daily capacity reaches 1000 square meters, and PCB

assembly can reach 100,000,0 units per month.

We deeply believe that our good service and experience will

completely meet you need. Integrity, value and innovation are the

forces that drive our success. We are the smart choice for you and

the trusted source at the center of your deal. Welcome the win-win

situation together.